LLC “Himmash apparat” offers to supply equipment for dehydration and desalting: electrical dehydrators, oil and water sumps, oil gas separators, heat exchangers, degassing units, etc.

In the design of electrical dehydrators offered by LLC ” HIMMASH-APPARAT” has been produced before operating experience of equipment, improved installation and operation conditions, can be manufactured in horizontal and vertical versions.

The design of electrical dehydrators include: fitting to accommodate the devices to control the water level, oil pressure and temperature. Completeness of delivery defined by the customer, based on the capabilities of its design organization and procurers. The basic package includes always economical, high-voltage power supplies, high voltage cables, insulators, power management, switching and protection shield signaling; at the request of the customer interface is supplied to the output signal from the control unit electrical dehydrators on a shared computer the whole plant. Additional equipment is determined by the results of the design documentation for the whole property as a whole. Standard series of electrical dehydrators up the volume from 1 to 200 m3.

In the construction provided with electrical dehydrators vertical oil riser, which is provided, and selecting the optimum processing temperature regent will reach the output unit water content of 0.5%.

Depending on the amount of salt and water content in the oil can be provided as a circuit with two (freshwater provides input) and one electrical dehydrators (without deep dehydration of fresh water).

Developed designs always provide for cleaning electrical dehydrators from deposited dirt and mechanical impurities.

Modern production with the use of metal-cutting and welding systems world-class under the supervision of leading experts in the field of oil treatment ensures high quality workmanship and full compliance with the published specifications.

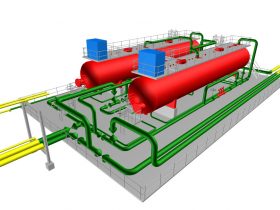

Description of the type design of the horizontal electrical dehydrator

Electrical dehydrators works as follows (the typical scheme)

Crude oil is heated in admixture with the wash water and demulsifier supplied through a feed distributor, it flows from the holes and is reflected from the impingement moves up through the first layer of the supernatant water, and then through a weak electric field between the electrode and the water level, then through a stronger field between the electrode and grounded flooring. During this movement the oil in the water drops grow in size and are deposited in the lower part of the apparatus.

Dehydrated oil is collected via two collections and removed from the machine.

Water collects in the bottom of the unit and is also derived from electrical dehydrators.

The water level is maintained automatically between the feed distributor and the lower electrode.