FILTRATION EQUIPMENT

Liquid and gas purification is performed using various devices that allow to achieve the desired effect with inertia, gravity, centrifugal forces, as well as electrical or magnetic interaction, mass transfer, mechanical filtration.

Effectiveness of these forces and differs depending on devices and exact particles composition. In particular, separating large fractions (particles more than 100 microns) are quite effective inertia and gravity forces; cleaning the gas stream from solid particles ranging in size from 10 to 100 microns and liquid particles (droplets) of 100 micron can be effectively achieved using centrifugal forces; for separating particles less than 5 microns in a gas stream usually recommended cartridge filter septum.

As a result, improving the design of different devices (filters, cyclones, separators, etc.), a combination of different devices design, named use limitations of certain physical forces to separate dirt particles can vary widely.

- Cartridge filters for liquids

- Cartridge filters for gases

- Magnetic filters

- Foam filters

- Centrifugal filters

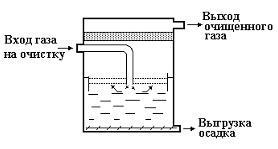

FOAM FILTERS

Apparatus for collecting solid, liquid and gaseous components of the exhaust gases of industrial production can be effectively used in the chemical, petrochemical, metallurgy, energy and other industries.

The advantages of the new design of the mass transfer device as compared with conventionally used are:

- High purification efficiency (up to 94-99%)

- Possibility of practically unlimited number of cleaning contaminated gas

- Low hydraulic resistance (30-150 mm water. v., depending on the specific conditions)

- Decrease of metal

- Minimum dimensions and the possibility of placing the device on the area available to the Customer

- Minimum energy costs

- Possibility of separating the collected components for reusability

- Lack of sewage

- Possibility to use as a working reagent industrial effluents containing harmful elements

- Ability to work in a continuous mode and cyclically

- Requires no maintenance during operation

Gas cleaning is carried out in the foam machine. Turbulence in the gas-liquid system is accompanied by the formation of an unstable, highly mobile foam due to the kinetic energy of the gas. The working foamable reagent water-scavenger is used, acids, alkalis, and other petroleum oils. Depending on the customer requirements for trapping components and the degree of purification.

At the same time addressing issues of purification of gas emissions from hazardous components, issues of effective utilization of the collected components.

The device has been successfully tested on a number of industrial enterprises of the chemical and metallurgical industries.

CENTRIFUGAL FILTERS

Designed for high-quality (99.9%) deep cleaning of gases (air, vapor) from dropping, fine, aerosol moisture fur. impurities.

Features separator:

- A high degree of separation (99.99%) at any pressure and performance.

- Absence of replaceable filter elements, rubbing and rotating parts.

- Operating environment – air, gas, gas-liquid mixture, saturated steam.

- The liquid content of the output, g / m3 – to 0.

- Suspended solids outlet – corresponds to “air cl.1” GOST 17433-80

- Loss of pressure, MPa (mm. Of water. Art.) – Not more than 0.003 (300).

- Stable operation in plug;

- A method of removing slurry – through the drain valve manually or automatically;

- Warranty period – 15 years.

Separators can be made for individual orders to various pressure and capacity, as well as equipped with an automatic condensate drain.

A high degree of separation is achieved by having sequentially operating during rotation of the gas stream multiple separation stages.

Using the proposed separator compared to peers, you can:

- reduce pressure loss and increase the performance of the separator through the vertical plates;

- qualitatively improve the structure of the rotating gas-liquid flow in an area between the package and the housing of the separator;

- dramatically increase the performance of the separator retaining its geometrical dimensions compared to its counterpart.